Capacity 800 Tons/Annum

(Spare Capacity: 500 Tons/Annum)

Currently we are developing every year 300 new products.

(Investment & Precision casting by Lost Wax, Feinguss & Micro Fusione)

- We export to

Germany

Australia

Spain

UK

USA

New Zealand

Malaysia

Soudi Arabia

Netherland

Canada

Thailand

About Us

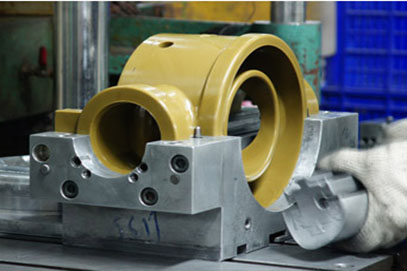

Amtech Technocast (ATC) is a versatile manufacturer, capable of producing highly customized products in the field of Investment Casting. Catering to quality-conscious niches, we compete against top-of-the-league. With a mission to deliver quality Investment casting products worldwide to the customers, our team is constantly developing new grades and applications to maintain and enhance our leading position. Consistent with the vision and values, Amtech technocast strives to rise to the new challenges and setting new standards to celebrate the delight of our customers by providing best possible products. The means envisaged to achieve this are high technology, productivity and manpower, consistent with modern management practice.

Our Sister Concern Facilities

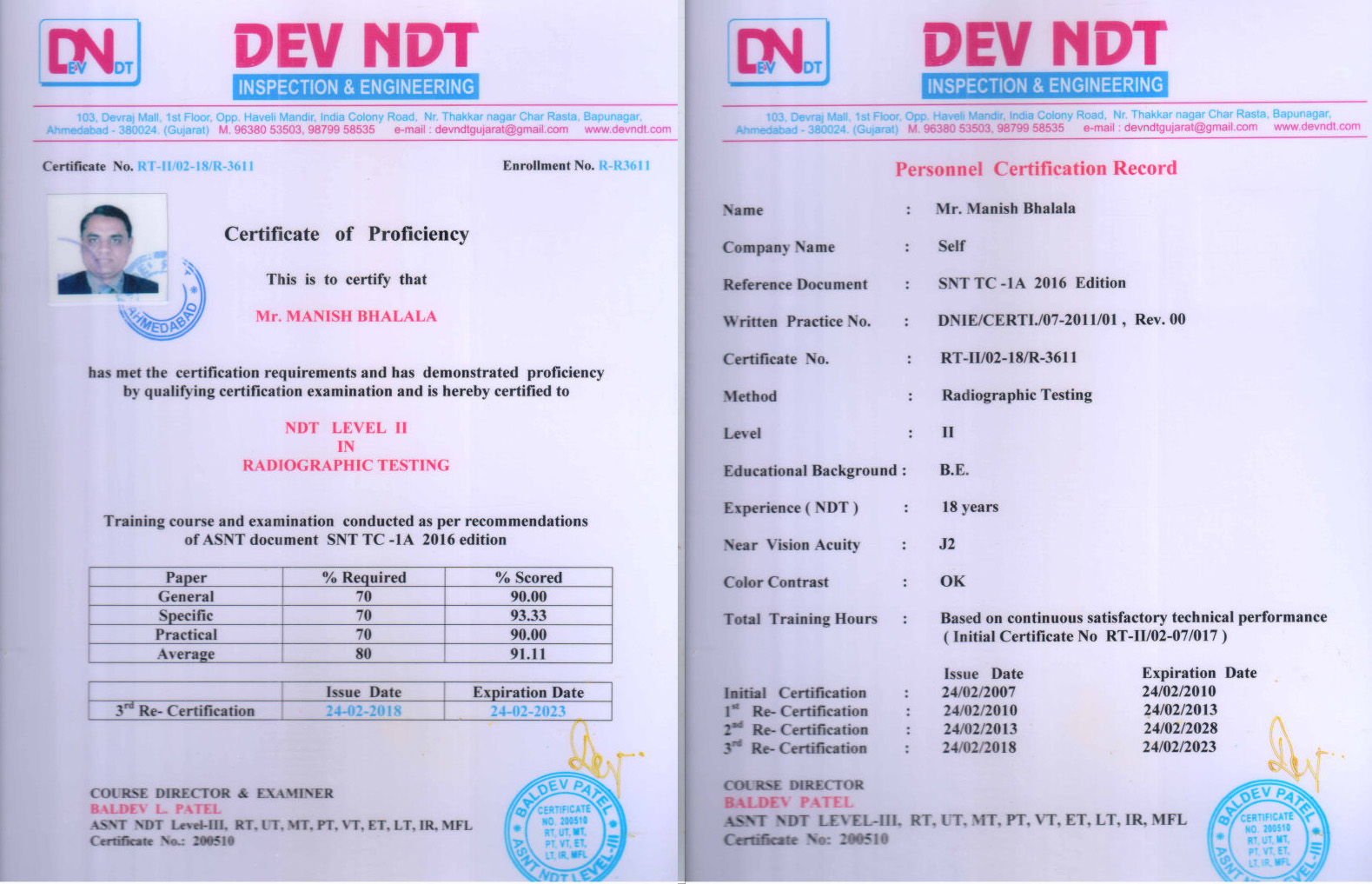

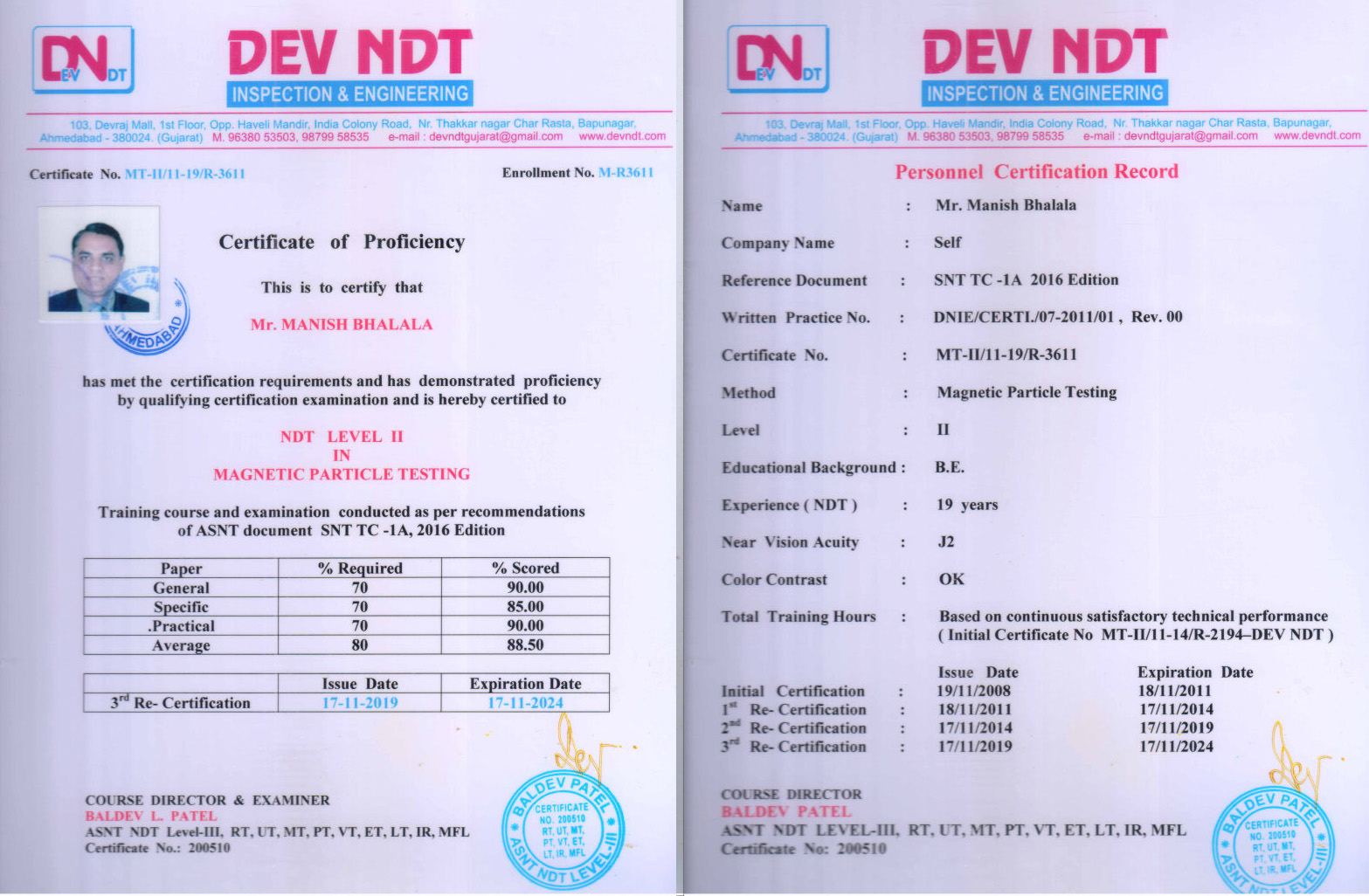

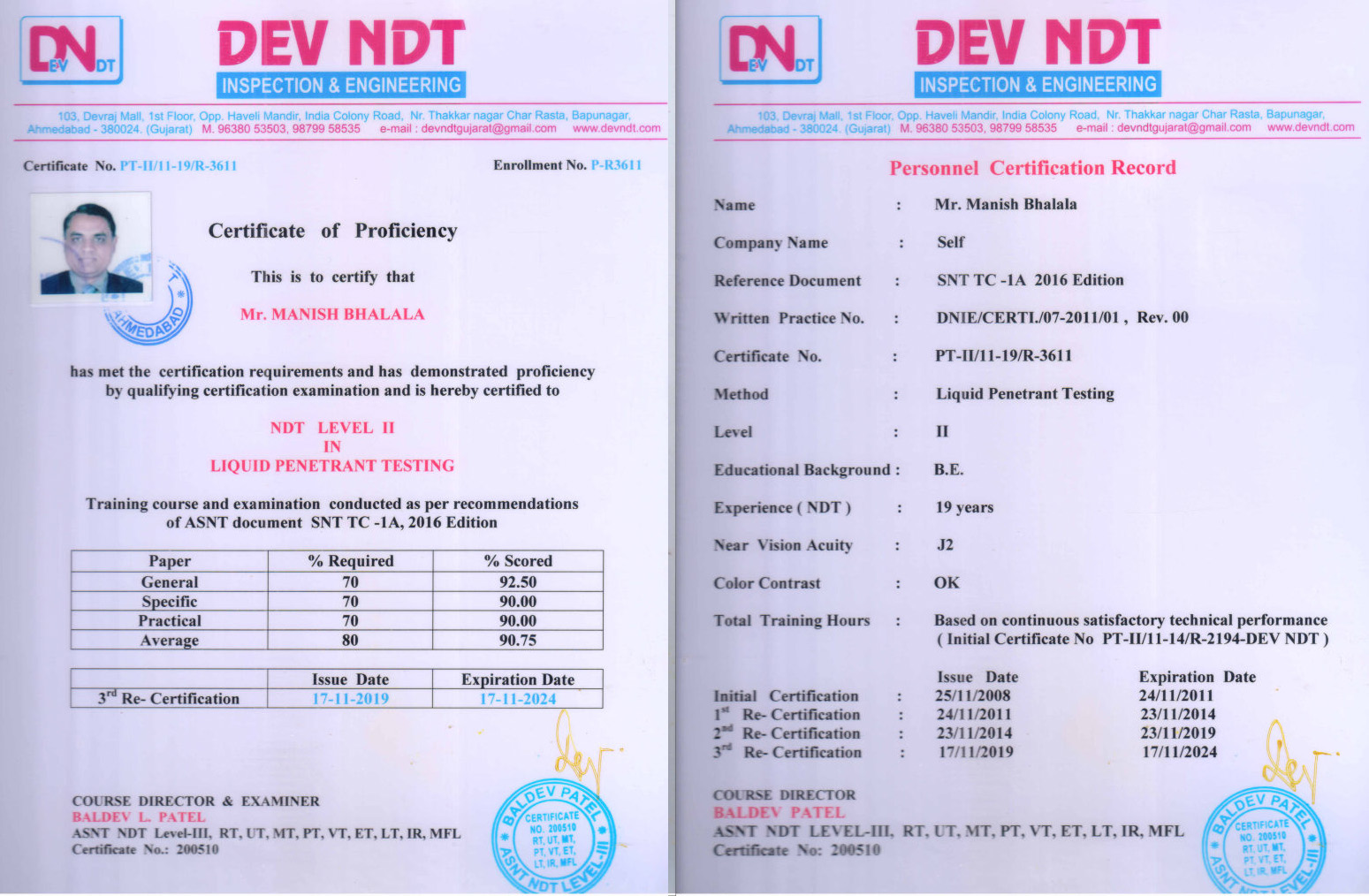

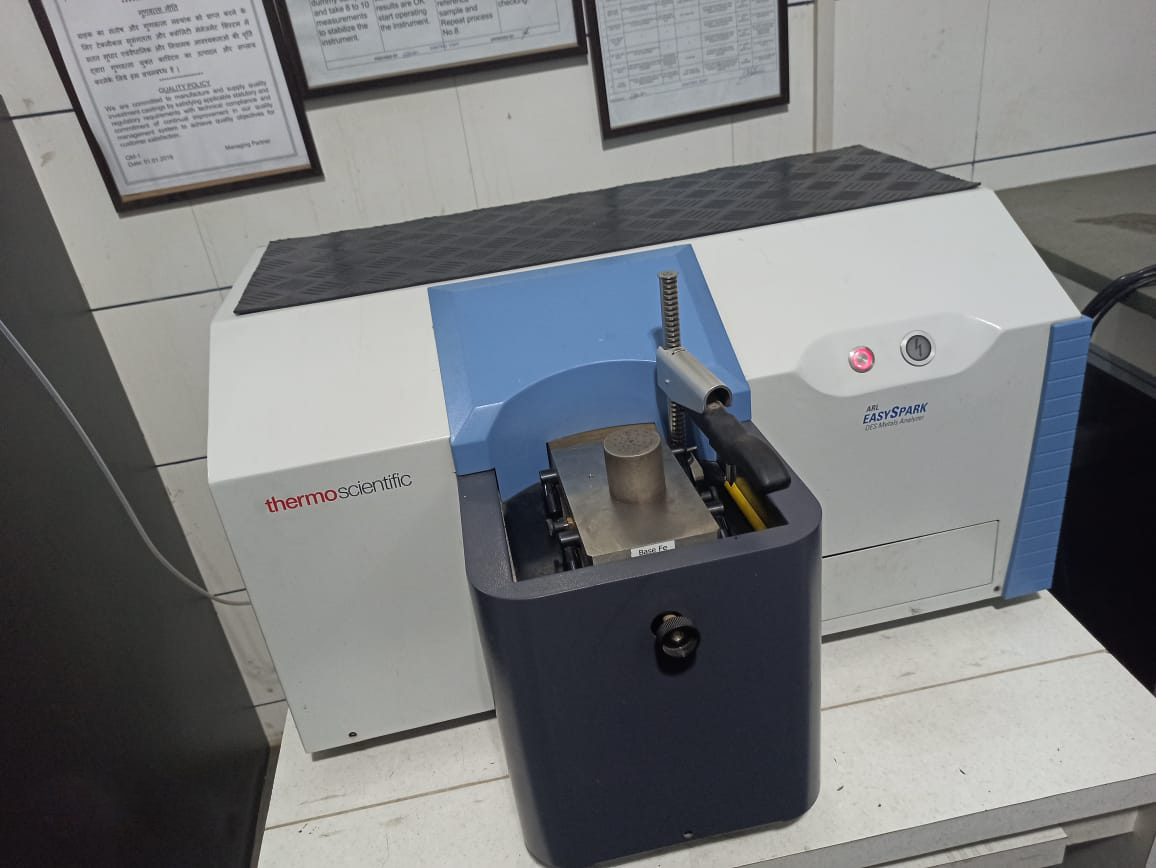

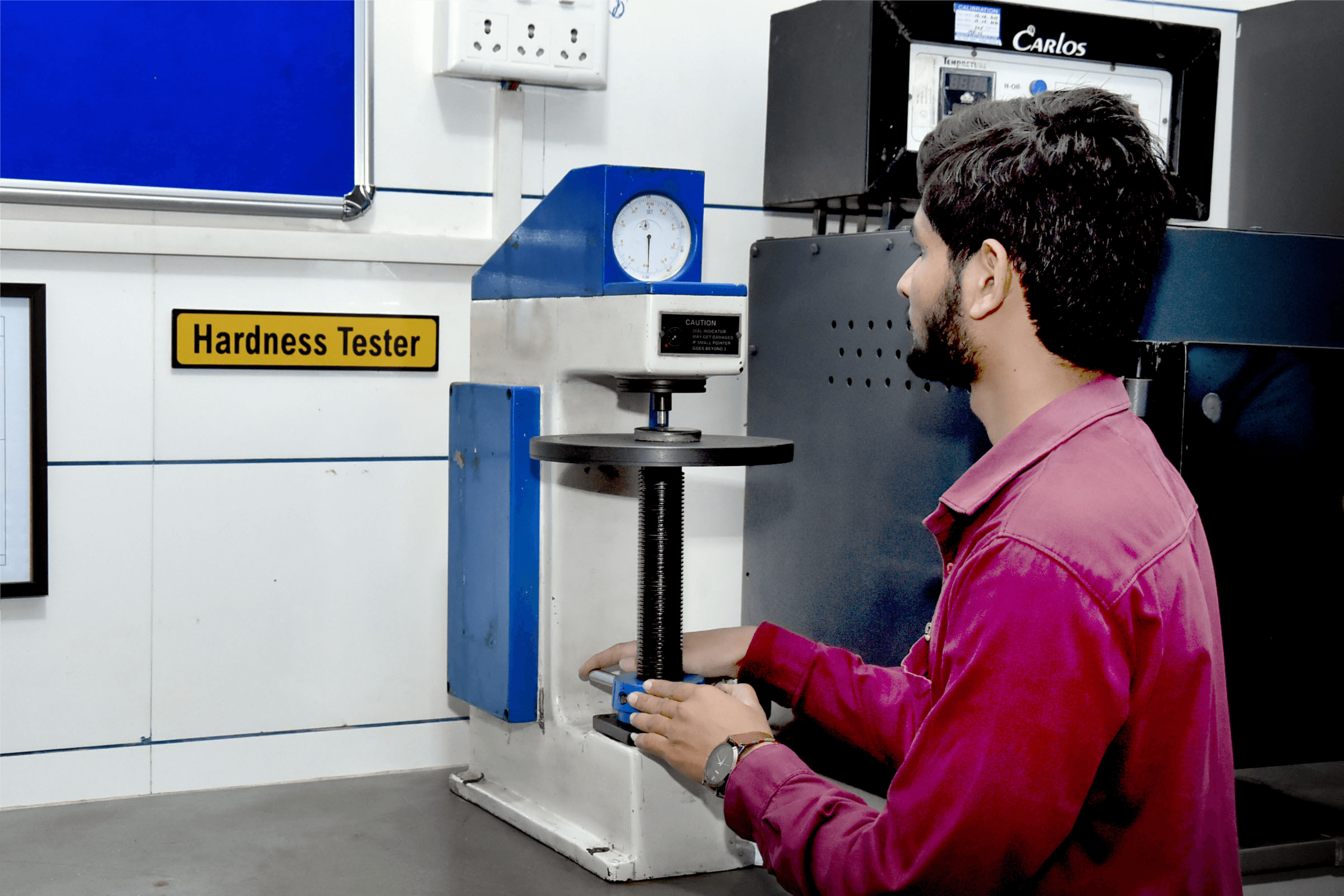

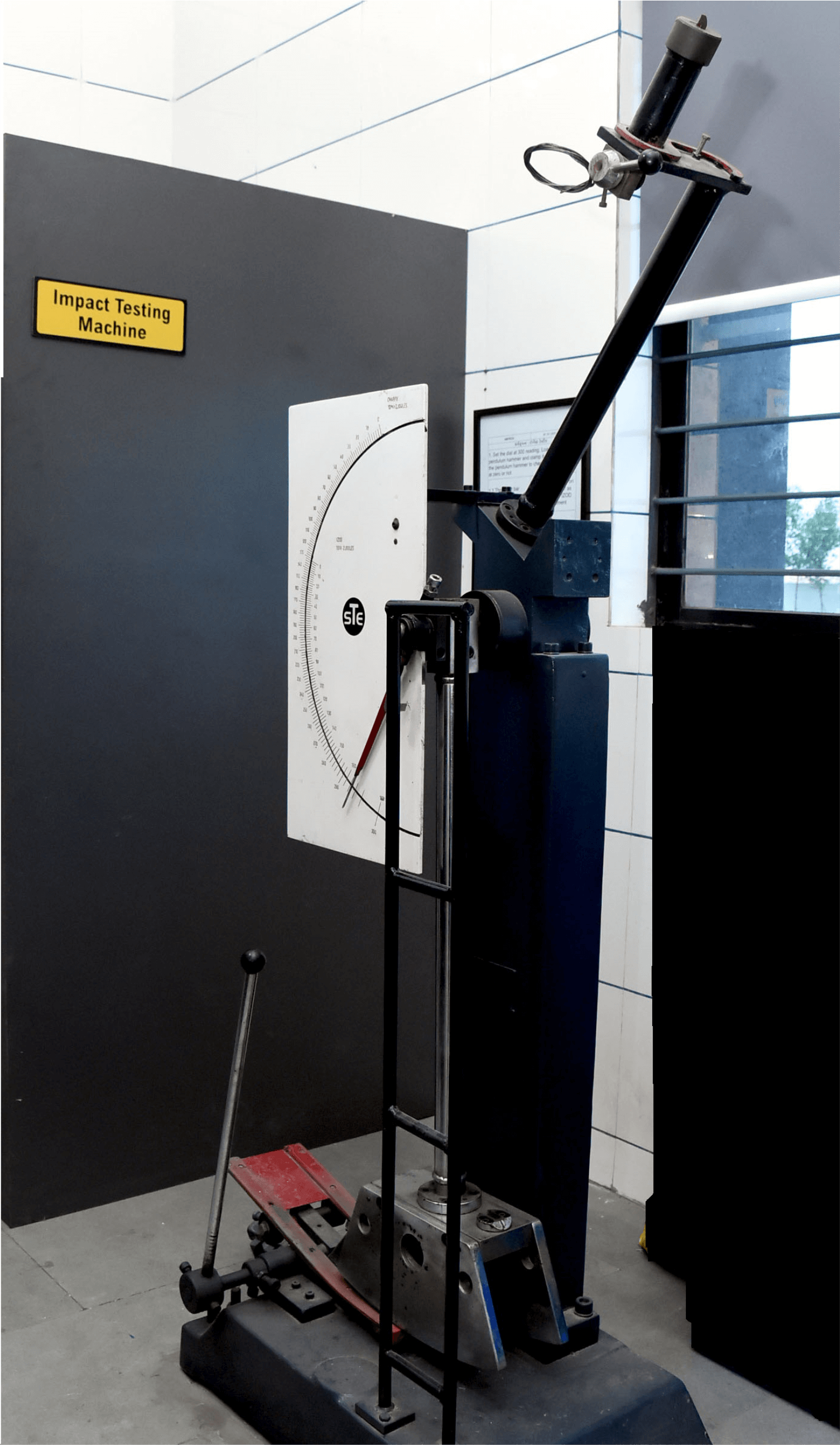

Quality Control

- Online Sampling

- Chemical and Mechanical Laboratories

- Heat Treating

- Design Assistance

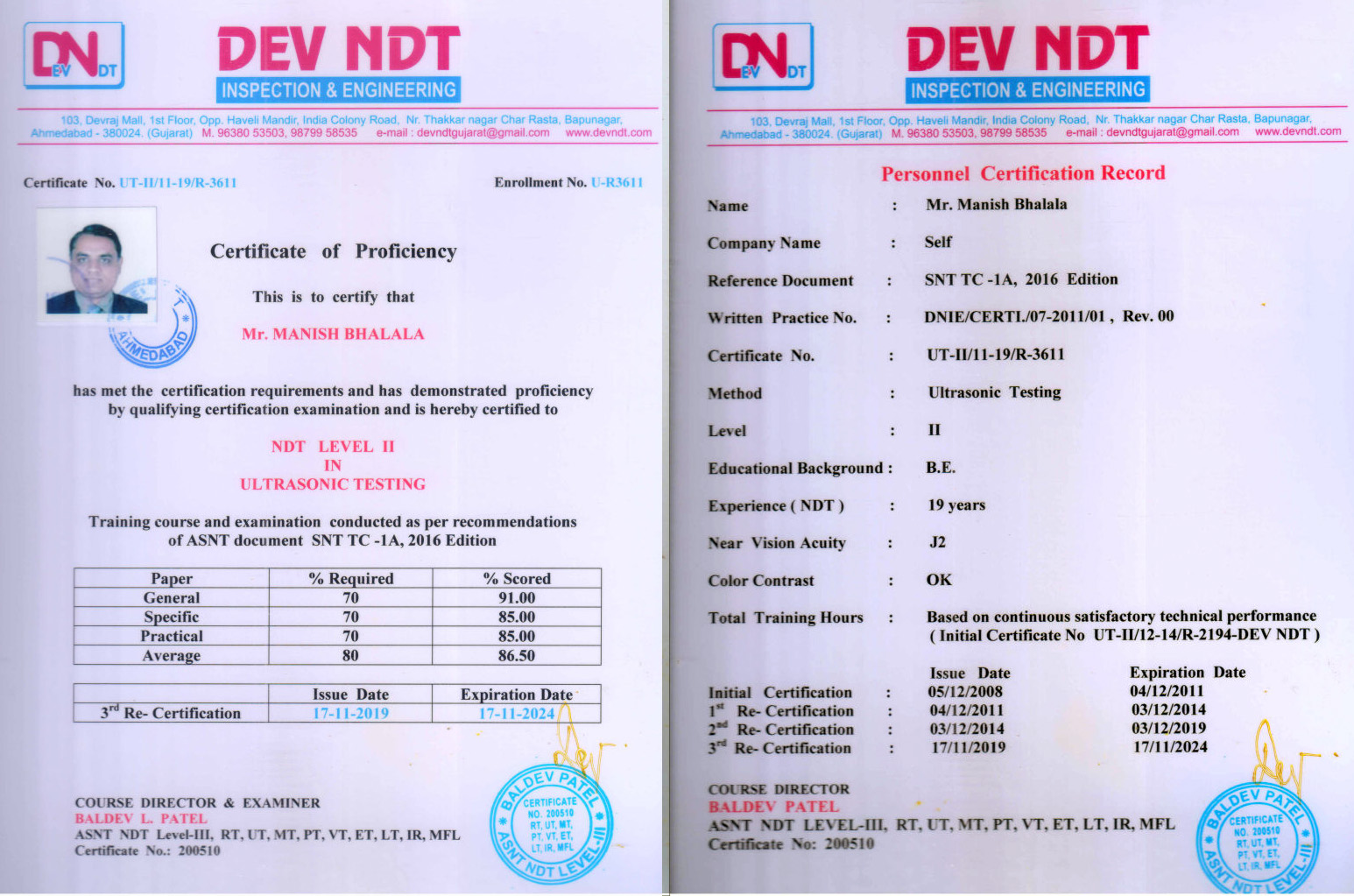

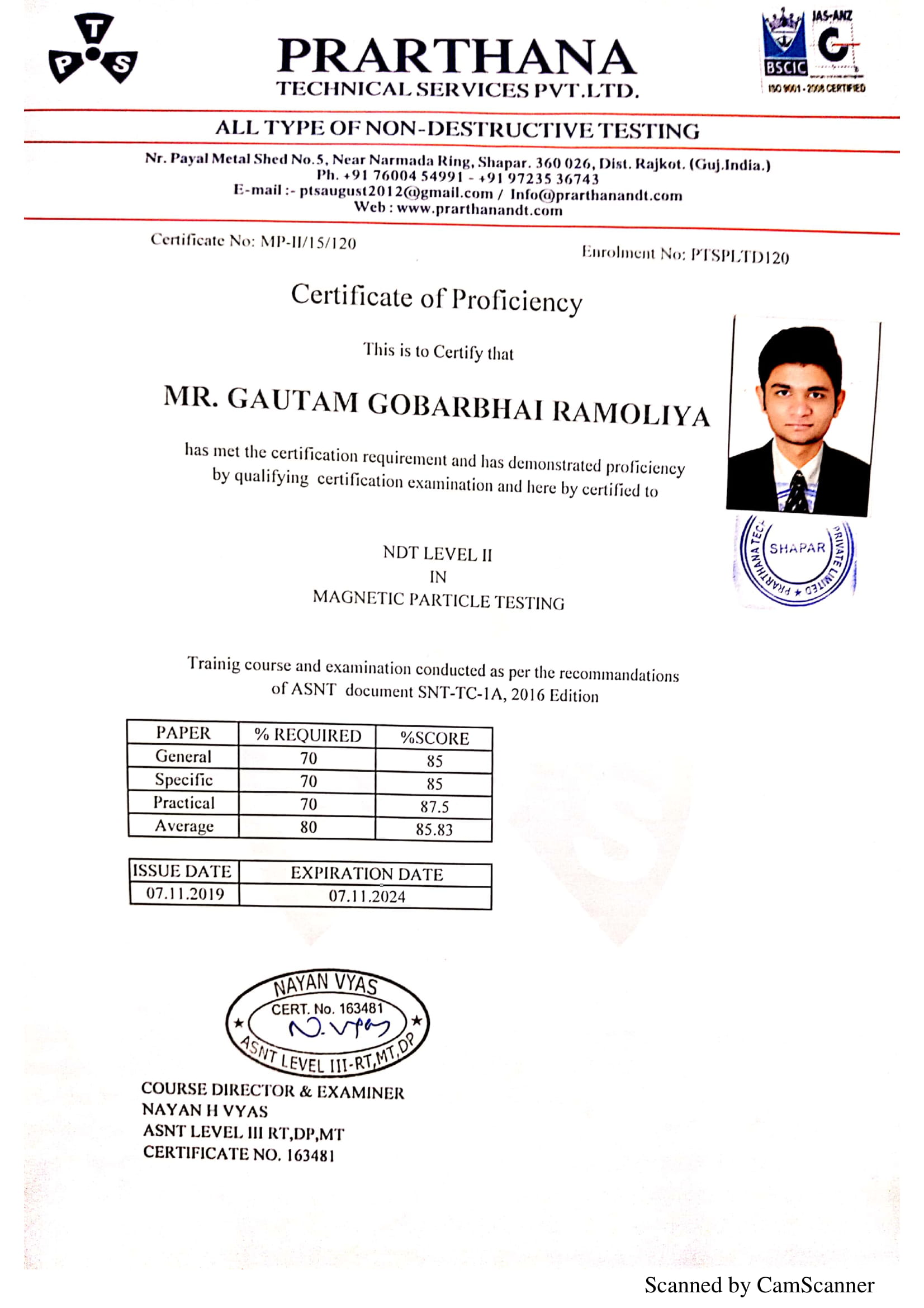

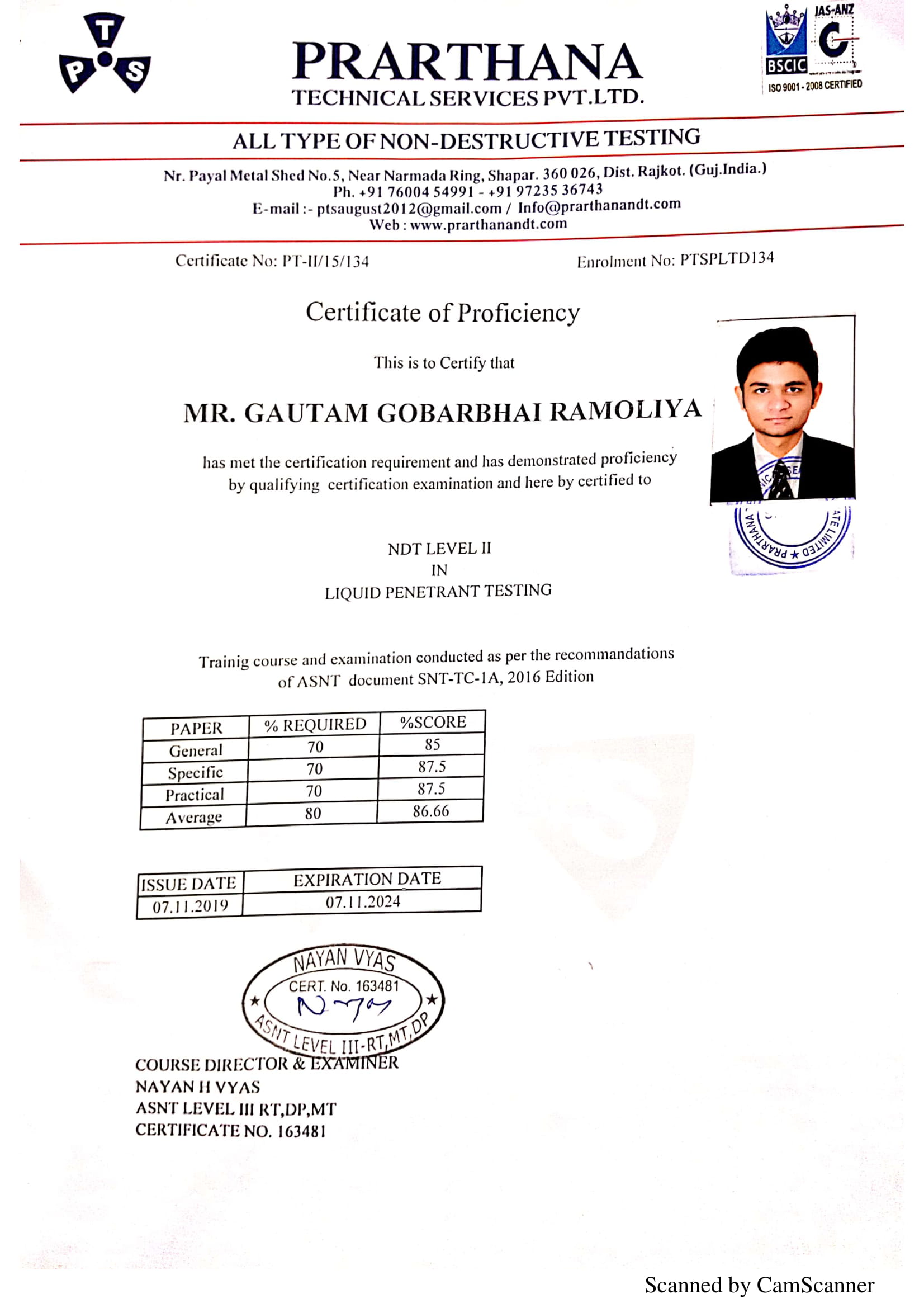

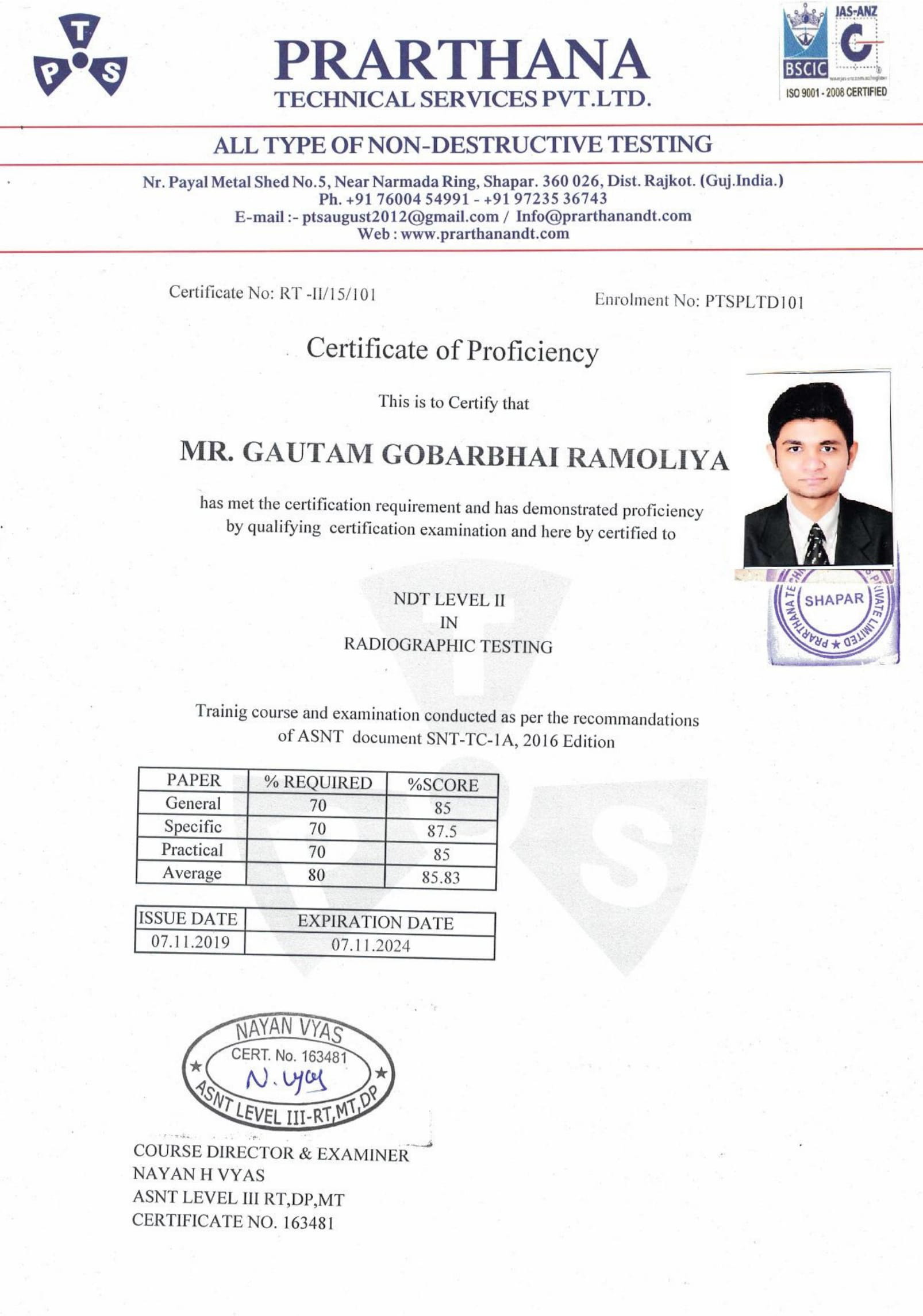

- Non-Destructive Testing (ASNT Level II approved inspector in RT, UT, MPT and LPT)

- Technical Assistance

- CMM (Make : Carl Zeiss) Accuracy 2 Micron

We operate a modern, fully staffed laboratory equipped with the latest equipment to verify that all incoming as well as finished products are as per specifications. We do online checks of every heat of molten metal meets our customers’ requirements. We also checks Tensile property , Hardness , Impact, Casting Soundness (Dye Penetrate, Magnetic Particle , Radiography Test) etc.

We also do have all the in house facilities to checks all incoming raw material like Waxes, Colloidal Silica, Ceramic Stuco, Zr Sand, Zr. Flour. In same we do test like Sp. Gravity, Gelling Test, Scratch Test, Sieve Analysis, Ph, Viscosity, Ash Content etc.From the testing of incoming metals and the control of alloys, to constant manufacturing controls and non-destructive testing, every step of the investment casting process is closely monitored and recorded as per ISO 9001 systems.Our process ensures the production of world class precision investment castings for our valued customer.

We operate a modern, fully staffed laboratory equipped with the latest equipment to verify that all incoming as well as finished products are as per specifications. We do online checks of every heat of molten metal meets our customers’ requirements.

Technical Capabilities

| ASTM | DIN /AISI | |

|---|---|---|

| A216 – WCB | 1.0619 / 1030/1020 | |

| A216 – WCC | 1.0619+N / 1020 | |

| A352 – LCC | 1.0619+QT , 1.1138 | |

| A352 – LCB | 1.0619+QT | |

| A217 – WC1 | 1.5419 | |

| A217 – WC4 | ||

| A217 – WC5 | ||

| A217 – WC6 | 1.7356 | |

| A217 – WC9 | 1.7379 | |

| A217 – WC11 | ||

| A217 – C5 | 1.7363 | |

| A217 – C12 | ||

| A217 – C12A | ||

| A743 – CA15 | 1.4008 / SS 410 | |

| A743 – CA40 | 1.4028 / SS 420 | |

| A743 CA-6NM | 1.4313 | |

| A297 – HF | 1.4825 | |

| A297 – HH | 1.4837 / SS 309 | |

| A297 – HI | 1.4846 | |

| A297 – HK | 1.4848 / SS 310 | |

| 1.4749 | ||

| A297 – HD | 1.4823 | |

| A351 – CF8 | 1.4308 / SS 304 | |

| A351 – CF8M | 1.4408 / SS 316 | |

| A351 – CF3 | 1.4306 / SS 304L | |

| A351 – CF3M | 1.4404 / 1.4409 / SS 316L | |

| A351 – CF8C | 1.4827 | |

| A351 – CF10 | 1.4308 / SS 304 | |

| A351 – CK20 | 1.4843 | |

| A351 – CH20 | ||

| A351 – CN7M | 1.4500 / Alloy 20 | |

| A351 – CG8M | 1.4431 | |

| A351 – CG3M | ||

| A351 – CF3MN | 1.4435 | |

| A351 – CD4MCu | 1.4460 / SS 2205 | |

| A351 – CG6MMN | 1.3964 | |

| A351 – CK3MCuN | ||

| A890 – GR1B/1C | CD4MCuN/CD3MCuN | |

| A890 – GR2A | CF8MN | |

| A890 – GR3A | CD6MN | |

| A890 – GR4A | CD3MN | |

| A890 – GR5A | CE3MN | |

| A890 – GR6A | CD3MWCuN | |

| CB7Cu1 | 1.4462 / SS 17-4 PH | |

| CB7Cu2 | ||

| A494 – M-35-1 | 2.4365 / Monel | |

| A494 – M-35-2 | ||

| A494 – M 30 C | ||

| A494 – N-12MV | Hast Alloy – B | |

| A494 – N-7M | ||

| A494 – CY40 | 2.4816 | |

| A494 – CW12MW | 2.4686 / Hast alloy C | |

| A494 – CW6M | ||

| A494 – CW2M | 2.4610 | |

| A494 – CW6MC | 2.4856 / Inconel 625 | |

| A494 – CX2MW | 2.4602 | |

| A494 – Cu5MCuC | 2.4858 / Inconel 825 | |

| A560 – 50Cr50Ni | ||

| A560 – 50Cr50Ni-Nb | 2.4813 | |

| A560 – 60Cr40Ni | ||

| STELLITE 3 | ||

| STELLITE 6 | ||

| STELLITE 21 | ||

| STELLITE 23 | ||

| Triballoy T 400 | ||

| Brass And Gun Metal |

Castings can be supplied as per equipment DIN, JIS, BS and GOST standards. Other than above, in general we can cast any material compositions as per customers specifications meeting international standards.

Investment castings tolerances reference international standard: VDG P690 & ISO 8062

Linear Tolerances

| Nominal size (mm) | D1 Tolerance (general dimensions) | D2 Tolerance (some functional dimensions) | Nominal size (mm) | DCTG - 6 | DCTG - 7 |

|---|---|---|---|---|---|

| 0 to 6 | ±0.15 | ±0.12 | 0 to 10 | ±0.26 | ±0.37 |

| 6 to 10 | ±0.18 | ±0.14 | 10 to 16 | ±0.27 | ±0.39 |

| 10 to 18 | ±0.26 | ±0.20 | 16 to 25 | ±0.29 | ±0.41 |

| 18 to 30 | ±0.26 | ±0.20 | 25 to 40 | ±0.32 | ±0.45 |

| 30 to 50 | ±0.40 | ±0.31 | 40 to 63 | ±0.35 | ±0.50 |

| 50 to 80 | ±0.45 | ±0.37 | 63 to 100 | ±0.39 | ±0.55 |

| 80 to 120 | ±0.55 | ±0.44 | 100 to 160 | ±0.44 | ±0.60 |

| 120 to 180 | ±0.8 | ±0.65 | 160 to 250 | ±0.50 | ±0.70 |

| 180 to 250 | ±1.20 | ±0.95 | 250 to 400 | ±0.55 | ±0.80 |

| 250 to 315 | ±1.30 | ±0.10 | 400 to 630 | ±0.60 | ±0.90 |

| 315 to 400 | ±1.80 | ±1.40 | 630 to 1000 | ±0.70 | ±1.00 |

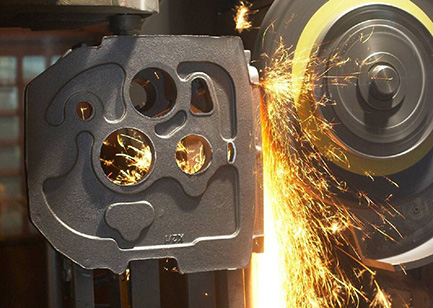

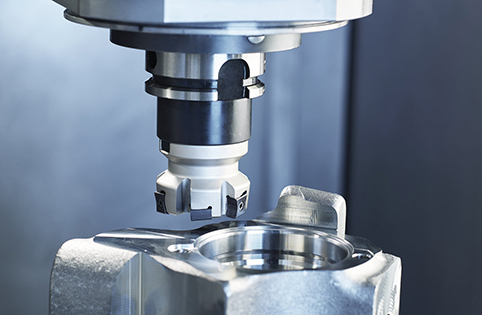

Machine Shop Detail

VMC

| Sr. No | Maker | X Travel | Y Travel | Z Travel | No of Machine |

|---|---|---|---|---|---|

| 1 | JYOTI-1260 WITH ROTARY | 1220 mm | 580 mm | 600 mm | 1 |

| 2 | JYOTI-850 | 800 mm | 500 mm | 500 mm | 1 |

| 3 | ACE-MCV450 | 800 mm | 450 mm | 500 mm | 1 |

| 4 | AACE-MCV450 2-PALLET | 800 mm | 450 mm | 500 mm | 1 |

| 5 | ACOSMOS VMC 1060 | 1000 mm | 600 mm/td> | 600 mm | 2 |

| 6 | COSMOS VMC 1060 WITH ROTARY | 1000 mm | 600 mm/td> | 600 mm | 2 |

CNC

| Sr. No | Maker | Diameter | Length | Bar Capacity | No of Machine |

|---|---|---|---|---|---|

| 1 | ACE, JOBBER XL | 400 mm | 400 mm | 38 mm | 8 |

| 2 | ACE, LT20XL | 500 mm | 700 mm | 63 mm | 4 |

| 3 | ACE, VTL 30/700 | 500 mm | 700 mm | 1 | |

| 4 | ACE, VTL 30/500 | 500 mm | 500 mm | 1 |

Spark Erosion Machine

| Sr. No | Maker | X Travel | Y Travel | Z Travel | No of Machine |

|---|---|---|---|---|---|

| 1 | SPARKONIX-S50 PLUS | 500 mm | 300 mm | 300 mm | 2 |

CMM (for dimension inspection)

| Sr. No | Maker | X Travel | Y Travel | Z Travel | No of Machine |

|---|---|---|---|---|---|

| 1 | ZEISS SPECTRUM II | 700 mm | 1000 mm | 600 mm | 1 |

Dynamic Balancing Machine

| Sr. No | Maker | Weight of Job | Max. Diameter | Max. Length | No of Machine |

|---|---|---|---|---|---|

| 1 | KRYSTAL-KHB-50 | 2-50 Kg | Ø 500 mm | 1200 mm | 1 |

| 2 | KRYSTAL-KHV-100 | 100 Kg | Ø 600 mm | Vertical | 1 |

Conventional Machine and General Machinery

| Sr. No | Description | No of Machine |

|---|---|---|

| 1 | TOOL ROOM LATHE | 3 |

| 2 | TOOL ROOM DRILL | 6 |

| 3 | TAPPING DRILL | 1 |

| 4 | MILLING MACHINE | 1 |

Laser Marking Machine

| Sr. No | Maker | No of Machine |

|---|---|---|

| 1 | STAR LASER TECHNOLOGY | 1 |

Hydro Pressure Testing Machine

| Sr. No | Maker | No of Machine |

|---|---|---|

| 1 | FERO ENGINEERING | 1 |

Our Process

1. Wax Injection

The process begins with production of a heat disposable pattern. This pattern is usually made by injecting wax into a metal die or mold. Pattern is injected in Horizontal Automatic Injection Machine. Water Cooling system is provided to reduce cycle time and to achieve dimension control of Pattern. For

very close dimension control pattern resting gauges also used.

2. Pattern Assembly

The wax patterns are attached by the gate to a central wax runner system. The runner system is called a sprue. Patterns, runners, and pouring cup compromise the cluster or tree. Radius is provided to all joints between pattern and runner. Same checked thoroughly before coating to avoid rejection due to sand

inclusions

3. Shell Building

The shell building technique involves dipping the assembly into a ceramic slurry and then into a bed of

extremely ne sand. After drying, the process is repeated. Up to 4 to 6 layers may be applied in this

manner. All Shell dried in Air Conditions in close range of temp. (22 – 26º C) & Humidity. We also used

Organic Fiber in secondary slurry bath to reduced cycle time and no. of coats. It also helps in

improvement of permeability of shells.

4. Dewax Operation

Completed shell is placed in a steam autoclave where the pattern melts and runs out through the gates

and pouring cup. Auto clave dewaxing operation maintain quality of wax compare to convensonal

dewaxing process.

5. Shell Pre Heating

The ceramic shell molds must be red to burn out the last traces of pattern material and to preheat the mold in preparation for casting, usually in the range of 800 to 1100 degrees centigrade. Amtech Technocast use rotary hearth furnesh with three burners which gives very much close control in shell temperature.

6. Metal Pouring

The preheated shell is lled with molten metal by gravity pouring. As the metal cools, the parts, gates, sprue, and pouring cup become one solid casting.

7. Gate/Riser Cutting

After the metal solidifies and cools, the ceramic shell is then removed by vibratory methods or water blasting

8. Heat Treatment

Casting to be shot Blasted to remove all small ceramic particles. Amtech Technocast also can supply casting with glass bead blasting or sand blasting if customer require.

9. Shot Blasting

Individual casting are removed from the cluster by means of a cut o wheel or weld cutting

10. Finishing Operation (Gate Grinding)

Remaining gate protrusions are removed by belt grinding.

11. Final Casting Inspection

Casting is Heat Treated as per Specications in 1 ton. capacity heat treatment furnace. Same has been

calibrated as per standard APA 6 A.

12. Machining

Finally casting is dimensionally and visually inspected, packed as per customer specification and dispatched. Before Despatch All testing to be done like Die Penetrate Test, Magnetic Particle Test, Radiography Test etc. based on customer specification.

13. Final Inspection

Foundry Certificates

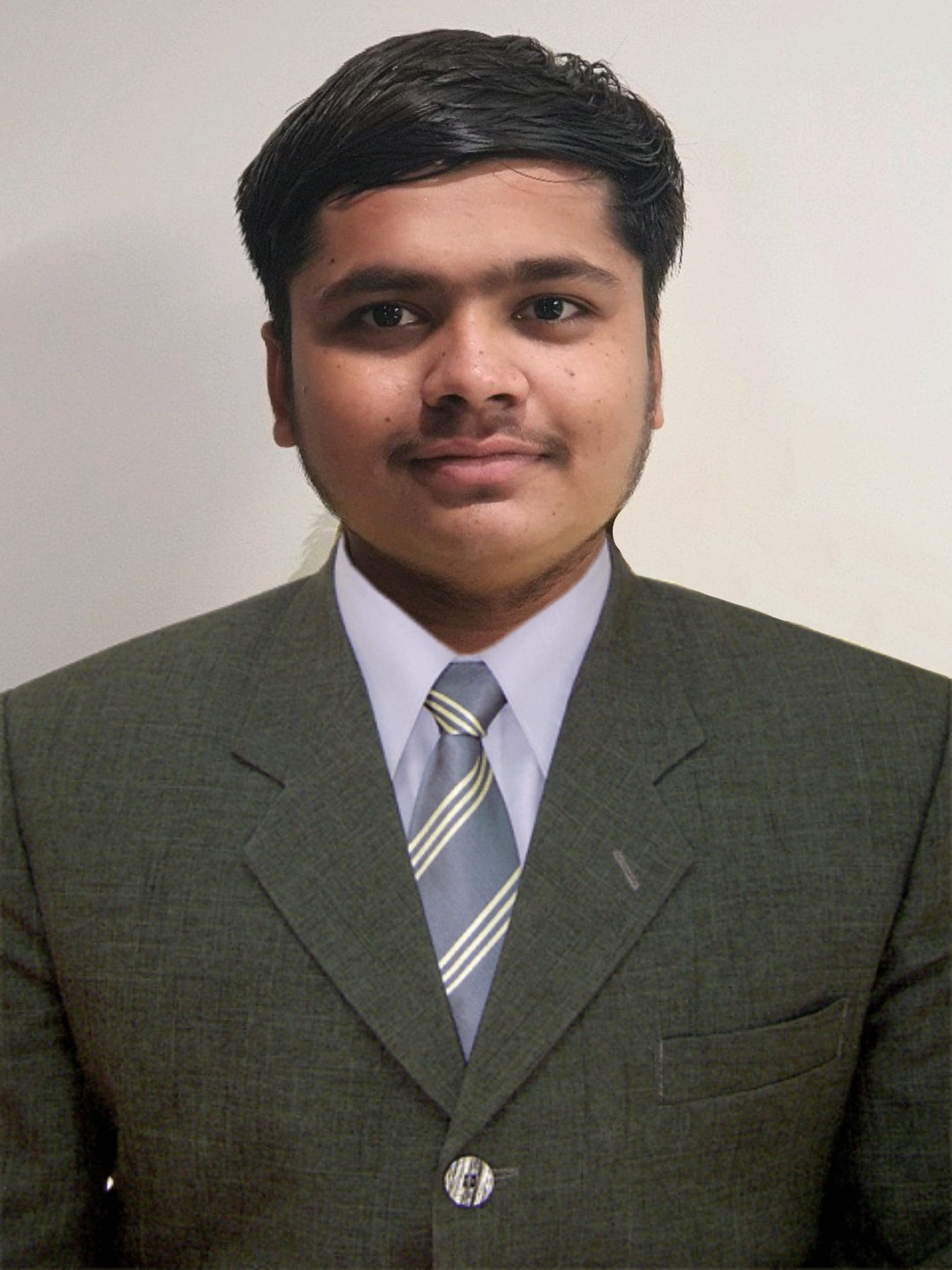

Our Team

Manish Bhalala

CEO (20 Years Experience)

Ramnik Bhalala

Co. CEO (8 Years Experience)

Jignesh Sojitra

Production Manager & Customer Support (8 Years Experience)

Dhirendra Joshi

Q.A. Manager (18 Years Experience)

Bharat Ghelani

General Manager (7 Years Experience)

Suresh Sojitra

Maintenance Head (15 Years Experience)

Ravi Bhalala

Production Engineer (3 Years Experience)

Harsh Bhalala

H.R. Manager (3 Years Experience)

Ravi Lathiya

Administator (8 Years Experience)

Jayesh Chavda

Development & Q.C. Wax (7 Years Experience)

Gautam Vanpariya

Q.C. Supervisor (3 Years Experience)

Parth Viradiya

Dispatch Manager (4 Years Experience)

Hardik Donga

Purchase Manager (3 Years Experience)

Hemant Varsankiya

Q.C. Final Inspection (3 Years Experience)

Nalin Makwana

Coating Incharge (15 Years Experience)

Gautam Ramoliya

Q.C. Chemical Mechanical Testing (5 Years Experience)

Vishal Vora

Lab Assistant (4 Years Experience)

Chandresh Dhameliya

Q.C. Engineer Melting (6 Years Experience)

Nilesh Goswami

Dispatch Incharge (3 Years Experience)

FAQ’s

The term “investment” may bring dollar signs before the eyes of those who are not familiar with the

process. Actually, it refers to the ceramic materialsthat are used to build a hollow shell into which molten

metal is poured to make the castings. The origin of the term investment comes from the solidmold

process where a plaster type material is poured or “invested” into a container that holds a clustered tree

of small plastic patterns that are identical to the casting being produced. After the plaster has set, the

disposable patterns are burned out leaving a hollow cavity into which the metal is poured.

The same holds true for the investment or “lost wax” casting process. Wax is injected into an aluminum

die to produce a pattern that is an exact replica of the part to be produced. For every casting, a wax

pattern must be manufactured. The patterns are then clustered around a coated sprue and repeatedly

dipped in to an agitated vat of ceramic and allowed to dry. After a shell thickness of approximately 3/8″

has been built; the molds are dewaxed by either ash ring at high heat (1400 degrees F) or autoclaving

(pressure and steam). The hollow shells are then preheated to 1800-2000 degrees F depending on the

alloy to be poured and the molten metal cast immediately into the hot shell. After cooling, the ceramic is

vibrated and blasted o the metal parts and discarded. The balance of the cleaning operations (cut o,

grind, heat treat, straightening, blast) are straight forward and quite similar to the other casting

processes.

Generally all ferrous and non-ferrous materials can be investment cast. On the ferrous side, carbon stell,

stainless steel, duplex stainless steel, super alloys, Nickel alloys, Cobalt alloys , tool and alloy steel along

with the 300 400, 15-5PH and 17-4PH stainless steels are most commonly poured. Most aluminum,

copper base, and other non-ferrous materials can be cast.

In addition, there are the “exotic” alloys used primarily in the aircraft engine industry to produce blades

and vanes. These alloys are primarily composed of nickel and cobalt with a variety of secondary elements

added to achieve specic strength, corrosion and temperature resistant properties.

Investment castings can be produced in all alloys from a fraction of a few grams (such as a dental brace

for a tooth) to over a few grams to 100 Kgs.

Typically, a linear tolerance of +/- .010 for the rst inch of geometry and +/-.005 for each inch thereafter is

standard for investment casting. This varies depending on the size and complexity of the part.

Subsequent straightening or coining procedures often enable even tighter tolerances to be held on one

or two specic dimensions.

Because the ceramic shell is built around smooth patterns produced by injecting wax into a polished

aluminum die, the resultant casting nish is excellent. A 125 micro-nish is standard and even ner

nishes (63 or 32) are not uncommon on aircraft engine castings.

While investment castings are generally more expensive than forged parts or those produced by other

casting methods, they make up for the higher cost through the reduction of machining achieved through the near net shape tight tolerances that can be held as cast. Many parts that require milling, turning,

drilling, and grinding to nish can be investment cast with only .020 – .020 nish stock.

Nothing varies more than lead times depending on part complexity and foundry capacity. Generally 8-10

weeks is typical for tooling and sample casting and 8-10 weeks for production.

Careers

Due to our continuous growth and ventures in the new markets, we are constantly looking for the best

qualied persons.

To apply please send your resume at inquiry@amtechtechnocast.com

Candidate are free to walk-in as well with prior appointment.

Contact US

Name of the Company :

Amtech Technocast

Mobile No :

Website :

www.amtechtechnocast.com

Plant :

Survey No. 54/2, Plot No. 1, Near Toll Tax Plaza, B/h. Tulsi Agro, Bharudi Road, Village: Pipaliya, Tal: Gondal, Dist: Rajkot - 360 311, INDIA.

Product:

Precision Investment Casting In Ferrous & Non Ferrous Metals By Lost Wax Process

Date of Commencement :

Plant : 2018

GSTIN No :

Plant : 24ABIFA2958C1ZP

CEO:

Mr. Manish Bhalala

Area :

Plant : 65000 Sq. Ft.

Installed Capacity :

Plant : 800 Tons/Annum

Spare Capacity:

Manufacturing Capabilities :

Single Piece Size: 750 x 750 x 600 mm (Max) Single Piece Weight: 0.050 Kg To 125 Kg

Installed Power :

Plant : 500 KVS

USA Sister Concern & Warehouse Address:

Danse Equipment Company Inc.

12201 Distribution PI

Beltsville MD 20705

Contact No. :+1(571)595-4154